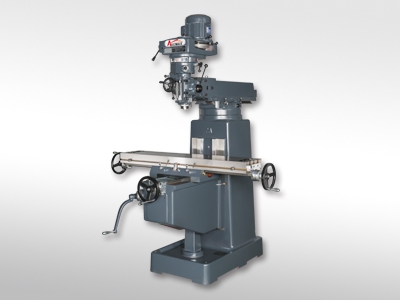

iB-1600

- High grade casting is annealed and stress-released, providing high rigidity and wear resistance

- Hardened and ground double-nut ballscrews on 3 axes, providing high precision movement, and reducing heat deformation.

- XYZ slideways, table and T-slot are hardened and ground

- 3 ways are coated with turcite-B

- Dovetail on X slideways, box ways on Y and Z

- 1:2 ratio timing belt boxes on XYZ to increase drive torque and save cost for axes motors

- XYZ axes are driven by servo motor, standard with pendent control box, and individual buttons for each function allows operator to work with ease

- YZ steel way covers protecting slidways and ballscrews from dust and coolant

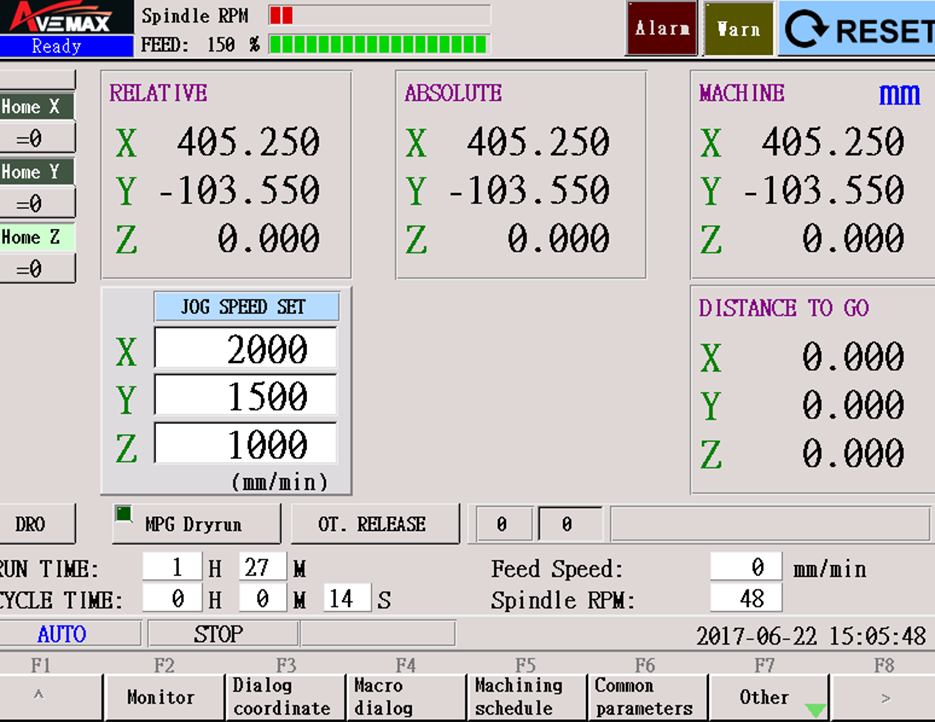

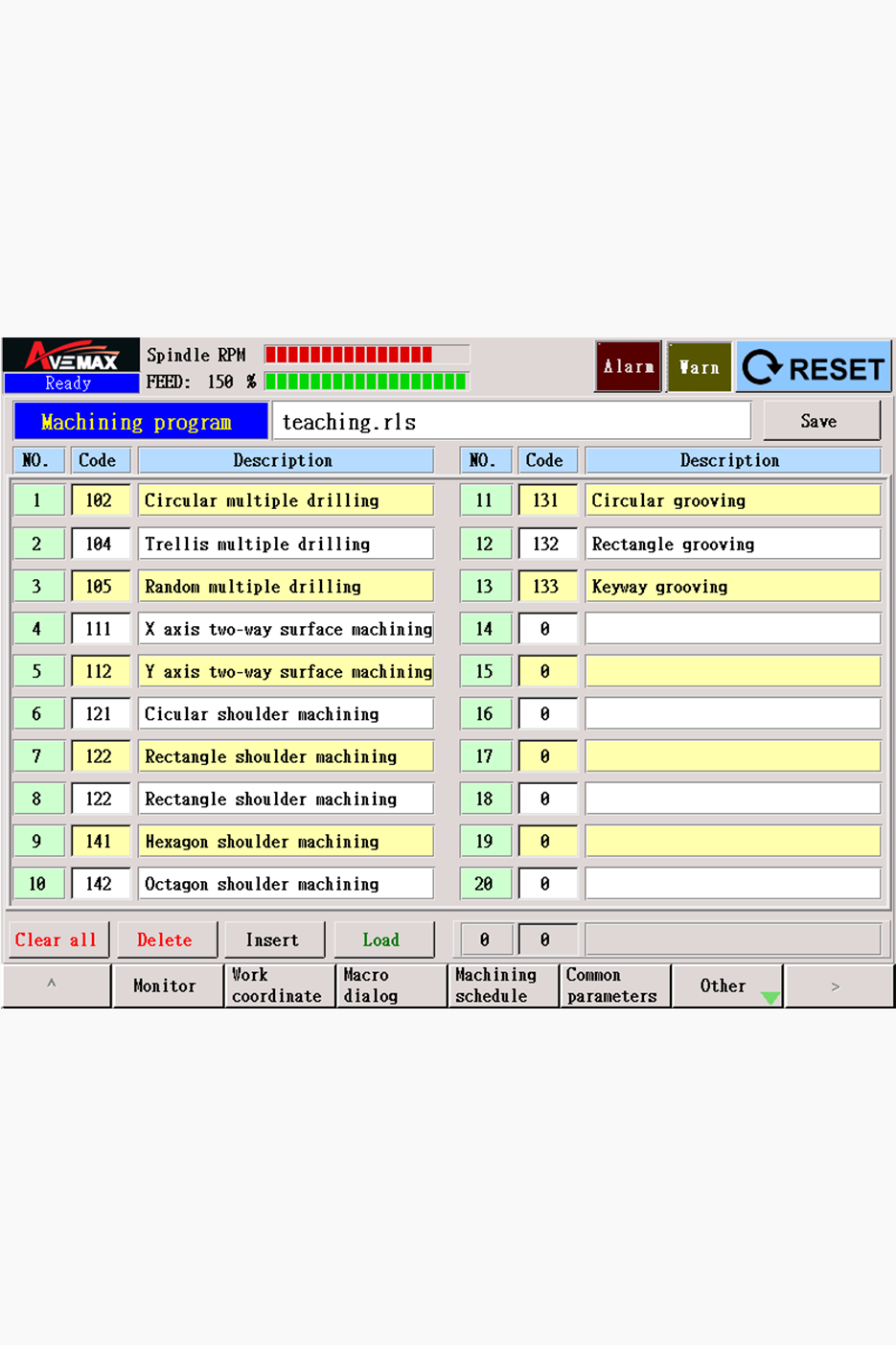

iPRO Intelligent Conversational Control System |

Features

|

DRO mode

|

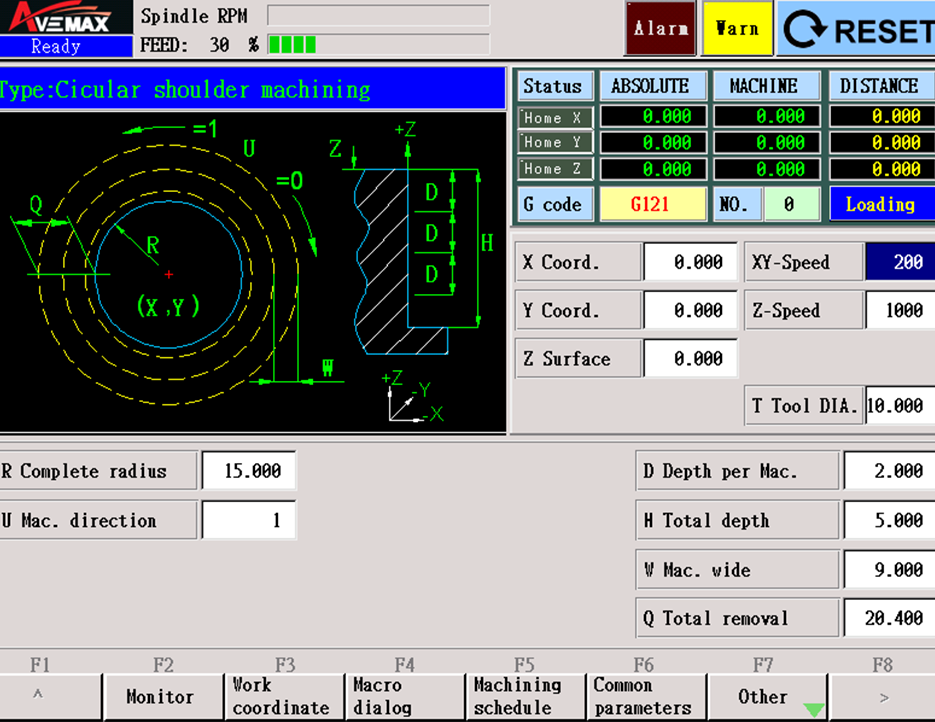

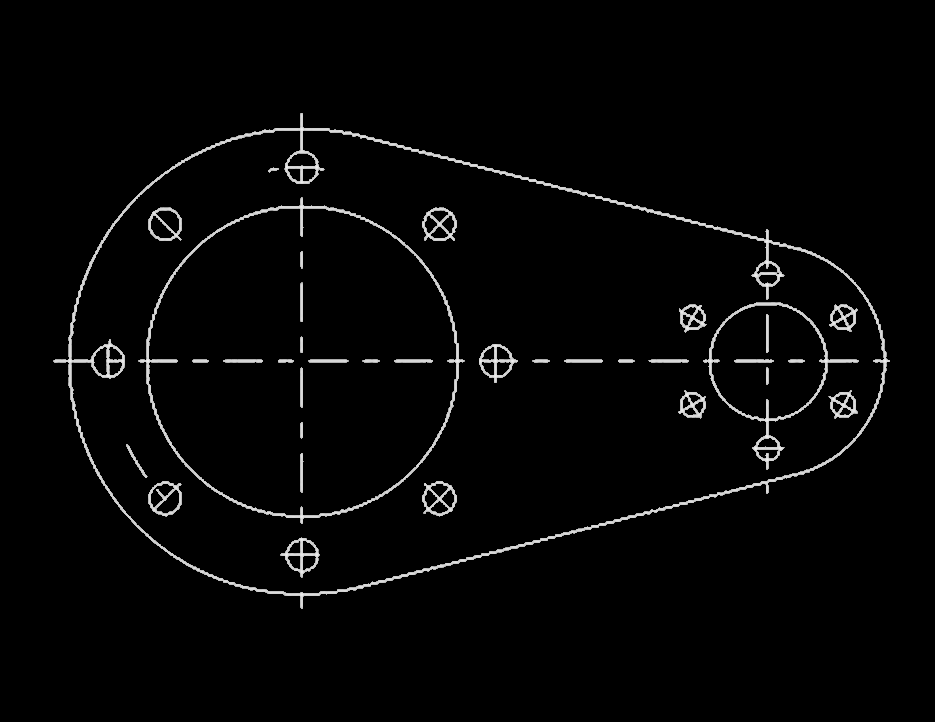

Programming

Program Storage

|

Help pages

Learning

Task scheduling

|

CAD/CAM input

|

| Specification | iB-1600 | |

| Travel | ||

| X/Y/Z travel | 1600/700/700mm | |

| Spindle nose to table surface | 70-770mm | |

| Spindle center to column surface | 670mm | |

| Table | ||

| Table size | 2200 x 500mm | |

| Table T-slot (No. x size) | 5 x 18mm | |

| Max. table load (kgs) | 1200kgs | |

| Spindle | ||

| Spindle taper | NST#40 | |

| Spindle speed (RPM) | 3600rpm | |

| Quill feed | 0.035/0.07/0.14mm | |

| Transmission | Variable speed (inverter) | |

| Quill travel | 140mm | |

| Head swivel (R&L) | +/- 45゜ | |

| Rapid feed rate XYZ (m/min) | 12M/min | |

| Motor | ||

| Spindle motor | 5HP inverter motor | |

| XYZ motor | 2Kw AC servo motor | |

| XYZ transmission | Timing belt pulley 1:2 | |

| Coolant pump | 1/4HP | |

| Machine size | ||

| Overall width (A) | 4800mm | |

| Overall depth (B) | 2300mm | |

| Overall height (C) | 2610mm | |

| Net weight | 4500kgs | |

We reserve the right to modify and improve the specification without notice. The specification shown above is for reference only.