iB-1000

- 5HP strong head can be swiveled 90 degrees right and left for angular machining

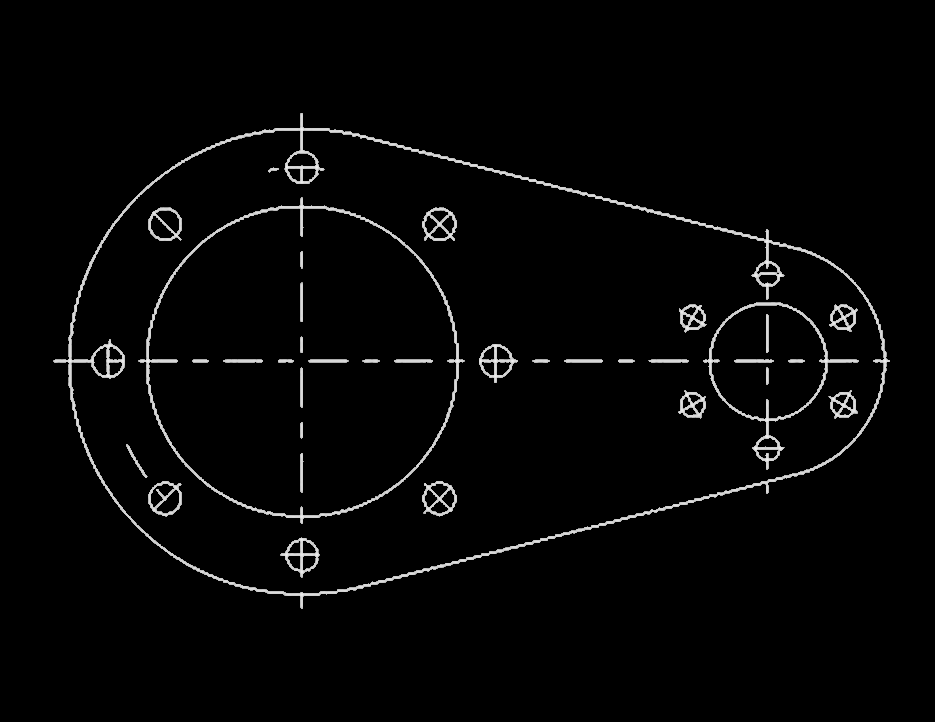

- Quill diameter 110mm(4.3”). NST#40 spindle

- XY axes high precision ballscrews, Z axis leadscrew (Z axis ballscrew by option)

- Heavy duty saddle length 1200mm (47.2”) support to table

- Rigid square ways on cross and column

- Licensed Meehanite casting

- Hardened and ground on X Y Z slideways and table

- Turcite-B coated on X Y Z axes slideways and gibs

- Counter-balance weight device for milling head

- Telescopic steel cover to protect the sildeways and ballscrew from dust

iPRO Intelligent Conversational Control System |

Features

|

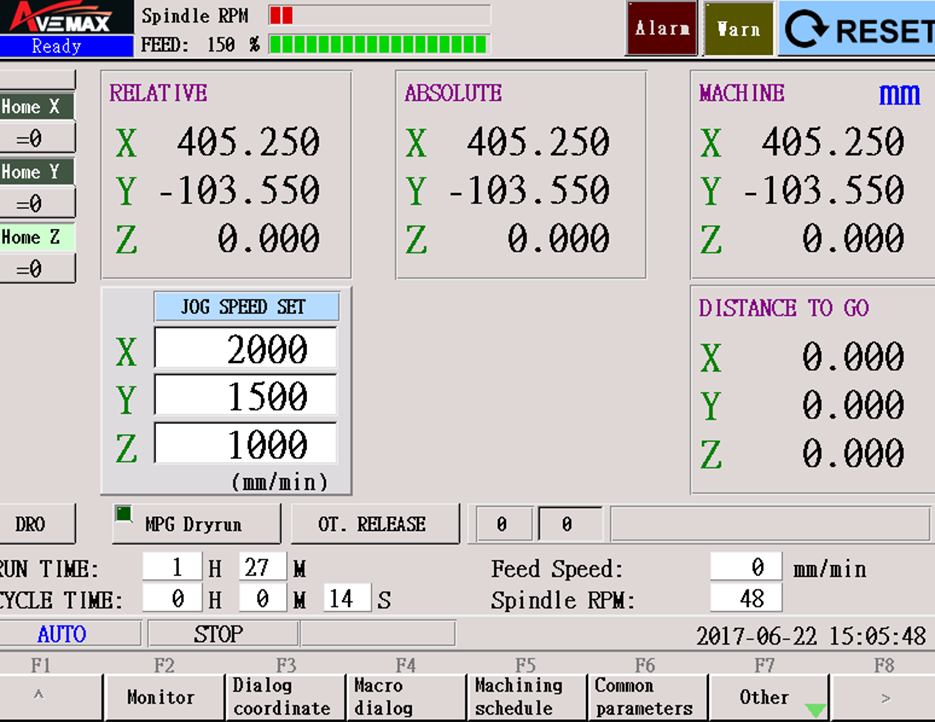

DRO mode

|

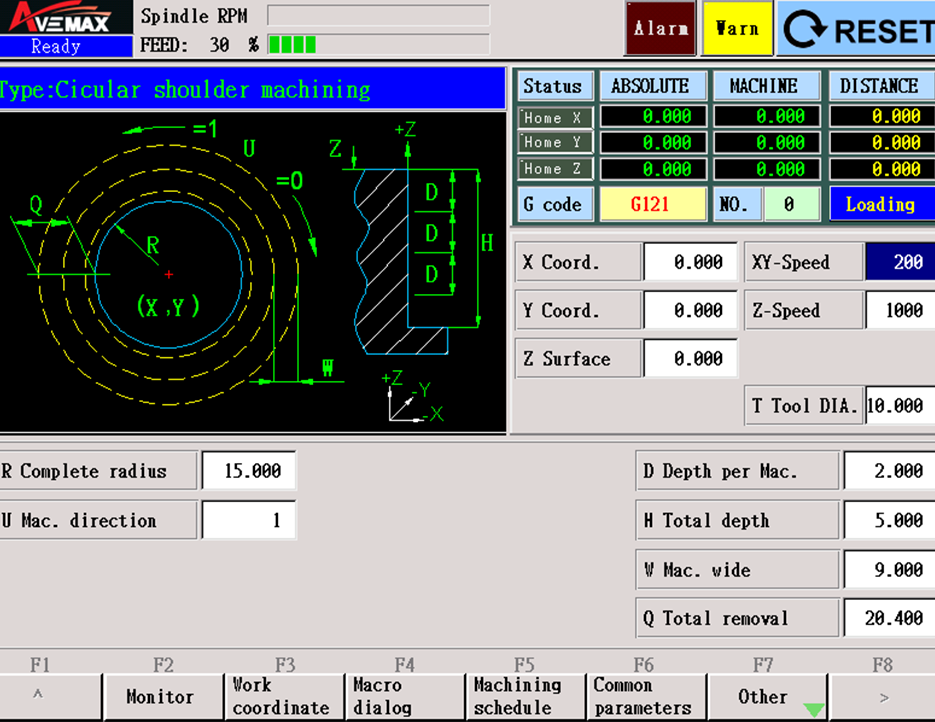

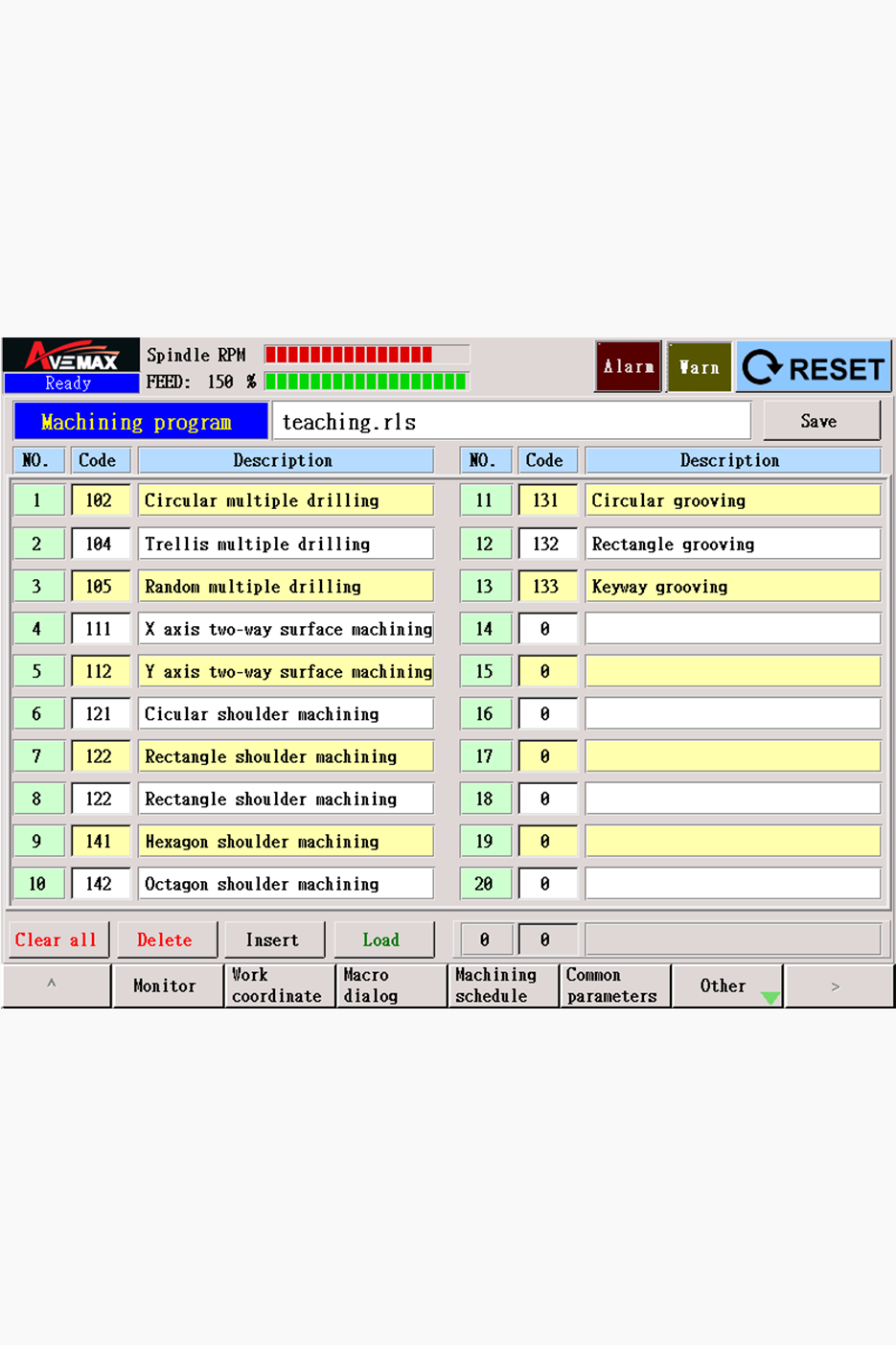

Programming

Program Storage

|

Help pages

Learning

Task scheduling

|

CAD/CAM input

|

| Specification | iB-1000 | |

| Travel | ||

| X/Y/Z travel | 1000/440/440mm | |

| Spindle nose to table surface | 85~585mm | |

| Spindle center to column surface | 490mm | |

| Table | ||

| Table size | 1270 x 380mm | |

| Table T-slot (No. x size) | 3 x 18mm | |

| Max. table load (kgs) | 800kgs | |

| Spindle | ||

| Spindle taper | NST#40 | |

| Spindle speed (RPM) | 3600rpm | |

| Quill feed | 0.035/0.07/0.14mm | |

| Transmission | Variable speed (inverter) | |

| Quill travel | 140mm | |

| Head swivel (R&L) | +/- 45゜ | |

| Rapid feed rate XYZ (m/min) | 5M/min | |

| Motor | ||

| Spindle motor | 5HP inverter motor | |

| XYZ motor | 1Kw AC servo motor | |

| XYZ transmission | Timing belt pulley 1:2 | |

| Coolant pump | 1/6HP | |

| Machine size | ||

| Overall width (A) | 2050mm | |

| Overall depth (B) | 2250mm | |

| Overall height (C) | 2090mm | |

| Net weight | 3100kgs | |

We reserve the right to modify and improve the specification without notice. The specification shown above is for reference only.